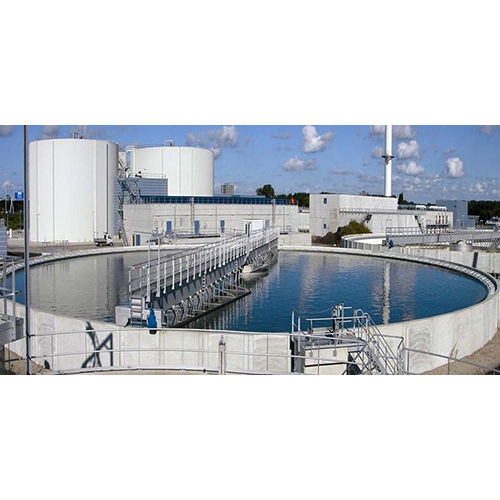

Industrial Effluent Treatment Plant

Price 400000 INR/ Unit

Industrial Effluent Treatment Plant Specification

- Application

- Industrial

- Water Source

- Industrial Effluent

- Material

- Stainless Steel

- Capacity

- 1000 Kiloliter/day

- Product Type

- Effluent Treatment Plants

- Power Source

- Electricity

- Operation Type

- Semi Automatic

- Color

- White

Industrial Effluent Treatment Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Industrial Effluent Treatment Plant

Our company offers high quality Effluent Treatment Plants. We offer customers effluent treatment plants that are sophisticated & innovative solution to purify the industrial effluent water. Our range of effluent treatment systems are used in most of the effluent parameters of factories and are designed to effectively solve the environmental pollution problem created by waste water of a company (without exposing it to the environment).

We Design, Manufacture, Supply, Erection and Commissioning Effluent Treatment Plant (ETP) on Turnkey basis for various types and natures of wastewaters, effluents which combines advanced physico-chemical treatment processes with tertiary polishing system for the removal of organic, inorganic, oil and grease, heavy metals & suspended solids.

OUR METHODOLOGY

We analyze the effluent samples for different effluent parameters as per nature and compositions, carry out the treatability studies by using different methods checking techno-commercial Feasibility and then designed treatment schemes, processes accordingly to suit the purpose and need.

Our ETP systems are very compact, tailor made designs, portable required very less foot-print to accommodate, energy efficient. The up-gradation, modification in the existing ETP system is possible to achieve desired limiting standard laid down by the Pollution Control Board (PCB).

THE PRINCIPLE

The principle of operation of ETP is Physico-Chemical treatment followed by Polishing Treatments like -Sand Filtration, Activated Charcoal treatment(Adsorption), Ozonisation (Chemical Oxidation), Ultra Filtration (UF), Reverse Osmosis (RO) and evaporation (If required).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 09AAGCK1103M1ZL

|

KKENWORLD PROJECTS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry